Generator Vibration Monitoring & Analysis

Industrial generators are critical assets in various sectors, and their health monitoring is crucial for uninterrupted operations. This generator vibration analysis report evaluates the Machine Saver's Trivibe vibration sensor for monitoring the health of industrial generators, considering both financial and technical aspects.

Technical Considerations

- High-Resolution Data Analysis: The Trivibe sensor’s capability to record over 50,000 samples per second offers high-resolution vibration data. This is particularly beneficial for detecting subtle changes in generator operation, which could indicate early signs of wear or impending failure.

- Customizable Data Output: With options for high pass, low pass, and band pass filters, the data output can be tailored to specific needs of different generator models, ensuring more relevant and actionable insights.

- Integration and Programming Flexibility: The sensor’s digital integration capability through an RS485 port and the availability of Python source code on Jupyter Notebooks make it highly adaptable to various control systems and monitoring setups.

- Durability in Industrial Environments: Manufactured in the USA and designed for a long lifespan, the Trivibe sensor is robust and suitable for the demanding environments where industrial generators operate.

- Wide Frequency Range: Its broad frequency range (0.8 Hz to 6000 Hz) enables the monitoring of a wide spectrum of vibration frequencies, which is crucial for comprehensive generator health assessment.

Financial Considerations

- Cost-Effectiveness of Predictive Maintenance: Early detection of potential issues allows for predictive maintenance, reducing the likelihood of costly emergency repairs and downtime. The high-resolution data provided by Trivibe can lead to significant long-term cost savings.

- Initial Investment vs. Long-Term Savings: While the initial investment in Trivibe sensors may be higher than some alternatives, the potential savings from avoiding major repairs and downtime can be substantial.

- Reduced Installation and Maintenance Costs: The ease of integration and minimal maintenance requirements of the Trivibe sensor reduce installation and ongoing operational costs.

- Warranty and Reliability: With a standard 1-year warranty extendable to five years, the sensor presents a reliable investment. Its capacity to meet high demand also attests to its industry acceptance and durability.

Conclusion

The Machine Saver's Trivibe vibration sensors for generators offers a compelling combination of technical advantages for monitoring the health of industrial generators. Its high-resolution data, customizable output, and robust design make it technically suitable for this application. Financially, although the initial investment may be higher, the potential for long-term cost savings through predictive maintenance and reduced downtime is significant. The sensor’s ease of installation and low maintenance requirements further enhance its financial appeal. Therefore, the Trivibe sensor is a prudent choice for industries looking to optimize the health and performance of their industrial generators.

We can customize vibration solutions to fit your needs

Request For QuoteRecommended Products

- TwinProx (sleeve or oil-lubricated bearings)

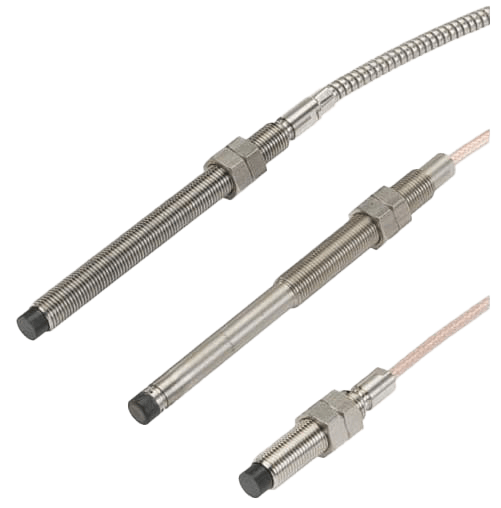

- Proximity Probes (sleeve or oil-lubricated bearings)

- Airvibe and Machine Gate (Wireless installation on Roller element bearings)

- Trivibe (Continuous near real-time data on roller element bearings)

Why choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us