Industrial Mixers Vibration Monitoring & Analysis

Addressing the vibration-related issues in industrial mixers and blenders is crucial for maintaining operational efficiency and equipment longevity. The Trivibe sensor from Machine Saver offers a sophisticated solution. The industrial mixer vibration analysis report evaluates the financial and technical aspects of implementing Trivibe sensors to solve common vibration problems in these industrial machines.

Technical Considerations

High-Resolution Vibration Data:Trivibe's capacity to record over 50,000 samples per second allows for precise detection of imbalance, misalignment, and other issues in mixers and blenders.

- Benefit: Early detection of minor issues before they escalate into major problems, avoiding unexpected breakdowns.

The availability of high pass, low pass, and band pass filters enables tuning the sensor to the specific vibration characteristics of different mixers and blenders.

- Benefit: Tailored monitoring for each machine, ensuring more relevant and actionable insights.

The RS485 port facilitates seamless integration with various control systems and gateways.

- Benefit: Simplifies the implementation process, allowing for a unified and efficient monitoring system.

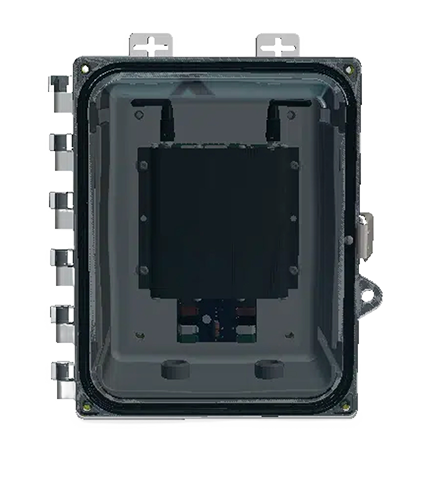

Designed and manufactured in the USA, the Trivibe sensor is built to withstand harsh industrial environments.

- Benefit: Reliable performance and longevity, even in demanding operational conditions.

Financial Considerations

Reduced Downtime and Maintenance Costs:By enabling predictive maintenance through early vibration issue detection, Trivibe can significantly reduce costly downtimes and maintenance interventions.

- Benefit: Long-term cost savings through improved operational efficiency and reduced repair costs.

While the initial investment in Trivibe sensors may be higher compared to traditional monitoring methods, the potential savings from avoiding major repairs and downtime are substantial.

- Benefit: A strong return on investment over time due to extended equipment life and reduced maintenance costs.

The sensor’s daisy-chain capability minimizes wiring complexity, reducing installation costs.

- Benefit: Cost-effective and less disruptive installation process.

Conclusion

Implementing the Trivibe sensor from Machine Saver in industrial mixers and blenders offers significant technical and financial advantages. Technically, its high-resolution data capture, customizable features, and robust construction make it highly effective for detecting and analyzing vibration-related issues. Financially, the sensor presents a cost-effective solution in the long run, with its potential to significantly reduce maintenance costs and prevent expensive unplanned downtimes. The Trivibe sensor is therefore a prudent investment for industries seeking to enhance the performance, reliability, and maintenance efficiency of their mixers and blenders.

We can customize vibration solutions to fit your needs

Request For QuoteRecommended Products

- Airvibe and Machine Gate (Wireless installation on Roller element bearings)

- Trivibe (Continuous near real-time data on roller element bearings)

Why choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us