Pump Vibration Monitoring & Analysis

Ensuring the effective monitoring of industrial pumps is vital for operational efficiency and longevity in various industries. The Trivibe Sensor stands as an exemplary solution for this purpose. This report explains why the Trivibe sensor is an optimal choice for pump vibration monitoring.

Advanced Data Resolution for Pump Analysis

The Trivibe sensor's capability to record over 50,000 samples per second provides high-resolution data essential for intricate pump vibration analysis. This high level of detail is crucial for the early detection of issues such as cavitation, misalignment, or bearing failures. By leveraging ML/AI for vibration visualization, the sensor facilitates predictive maintenance, thereby reducing unexpected downtime and prolonging pump life.

The sensor’s customizable dynamic data output, including options like high pass, low pass, and band pass filters, allows it to be precisely tuned to the specific vibration characteristics of different pumps. Its digital integration via an RS485 port ensures compatibility with a variety of control systems. Additionally, the availability of source code in Python on Jupyter Notebooks makes it highly adaptable and easy to integrate into diverse pump monitoring systems.

Manufactured in the USA, the Trivibe sensor is designed for durability, an essential attribute in the challenging environments where pumps operate. It can be custom designed for specific pump applications and offers various mounting options. The standard 1-year warranty, extendable to five years, and the ability to meet high annual demand, signify its reliability and industrial acceptance.

The sensor's broad frequency range (0.8 Hz to 6000 Hz) and its internal RTD for temperature measurement make it suitable for a wide array of pump types. Its compliance with the IP68 waterproof standard and capability to operate submersibly ensures reliable performance under diverse operational conditions.

The daisy-chain capability of the Trivibe sensors minimizes wiring complexity and installation costs, particularly beneficial in facilities with multiple pumps. This feature, along with the sensor's longevity and minimal maintenance requirements, underscores its cost-effectiveness.

Cavitation, a common and detrimental phenomenon in pumps, occurs when vapor bubbles form and collapse in the pump's fluid, causing damage over time. Continuous monitoring (not periodic) with the Trivibe sensor is key to detecting early signs of cavitation. The sensor's high-resolution data allows for the identification of specific vibration patterns indicative of cavitation, enabling timely intervention before significant damage occurs. This proactive approach not only prolongs the pump's lifespan but also maintains operational efficiency and safety standards.

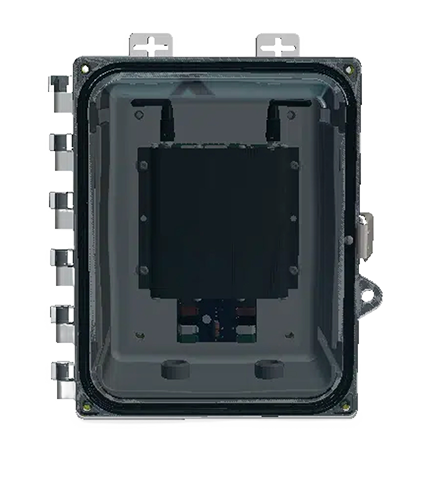

The Trivibe Wireless Sensor is a highly capable, adaptable, and robust tool for pump vibration monitoring. Its advanced data resolution, customizable features, durability, and wide application range make it an ideal choice for industrial environments. Its effectiveness in preventing cavitation through continuous monitoring, combined with ease of integration and cost-effective installation and maintenance, further reinforces its suitability for pump monitoring. It is, therefore, highly recommended for industries looking to enhance the performance and maintenance of their pump systems.

We can customize vibration solutions to fit your needs

Request For QuoteRecommended Products

- TwinProx (sleeve or oil-lubricated bearings)

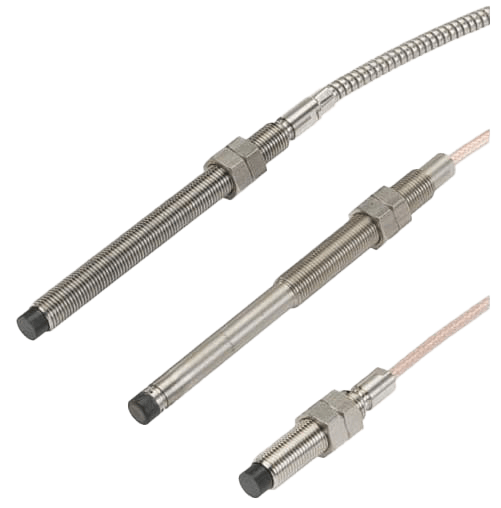

- Proximity Probes (sleeve or oil-lubricated bearings)

- Airvibe and Machine Gate (Wireless installation on Roller element bearings)

- Trivibe (Continuous near real-time data on roller element bearings)

Why choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us