Motor Vibration Monitoring Systems

In the rapidly advancing industrial sector, precise and reliable monitoring of machinery, particularly motors, is crucial. The Trivibe Sensor emerges as a remarkable solution, particularly tailored for this purpose. This report aims to elucidate the reasons why the Trivibe sensor is an optimal choice for motor vibration monitoring.

High-Resolution Data for Advanced Analysis

The Trivibe sensor's capability to capture over 50,000 samples per second ensures high-resolution data. This is vital in detecting even the minutest anomalies in motor operations, which can be critical in preventing potential failures. High-resolution data is essential for effective machine learning (ML) and artificial intelligence (AI) applications in vibration analysis, leading to predictive maintenance and reduced downtime.

Flexibility in data output, with options like high pass, low pass, and bandpass filters, allows for tailored monitoring suited to specific motor characteristics. The sensor's digital integration via an RS485 port ensures compatibility with various gateways and systems. Furthermore, the availability of source code in Python on Jupyter Notebooks simplifies integration and programming, making it highly adaptable to diverse industrial needs.

Designed and manufactured in the USA, the Trivibe sensor is built for longevity. Its customizable design for specific machine applications, multiple mounting options, and a standard 1-year warranty, extendable to 5 years, underscore its reliability. The sensor's capacity to fulfill over 10,000 units per year demand indicates its proven efficacy in industrial settings. Additionally, the redundancy in accelerometers enhances its accuracy and lifespan.

The sensor's wide frequency range (0.8 Hz to 6000 Hz) and its ability to measure temperature using an internal RTD make it exceptionally versatile. It is suitable for various environments, including hazardous locations and submersible conditions, up to 30 feet in freshwater, adhering to the IP68 waterproof standard. The impact monitoring mode is particularly useful for specific industrial applications like compressor cylinders and reciprocating pumps.

The option to daisy-chain the sensors significantly reduces wiring installation costs. This feature, coupled with its long lifespan and minimal maintenance requirements, makes the Trivibe sensor a cost-effective solution for motor vibration monitoring.

Conclusion

The Trivibe Wireless Sensor stands out as a highly advanced, adaptable, and reliable solution for monitoring industrial motors. Its high-resolution data capabilities, customizability, robust design, and versatility in various industrial environments make it an invaluable tool. The sensor's integration ease and cost-effectiveness further reinforce its suitability for widespread industrial application. In light of these factors, the Trivibe sensor is highly recommended for organizations seeking to enhance their motor monitoring and maintenance strategies.

Comprehensive Evaluation of AirVibe Wireless LoRa Sensor for Enhanced Monitoring of Industrial Motors

In the dynamic and evolving landscape of industrial technology, the precision and reliability of equipment monitoring, especially for motors, are paramount. The AirVibe Model VIBR8 Wireless LoRa Sensor presents a sophisticated solution designed specifically for this application. This technical report delves into the multifaceted capabilities of the AirVibe, demonstrating its suitability as an advanced tool for industrial motor monitoring.

The AirVibe sensor boasts an impressive data acquisition rate exceeding 24,000 samples per second, facilitating the capture of high-resolution vibrational data. This capability is instrumental in identifying subtle anomalies in motor function, crucial for preemptive maintenance measures. The sensor's high-resolution data acquisition is pivotal in refining machine learning (ML) and artificial intelligence (AI) algorithms for advanced vibration analysis, culminating in predictive maintenance models and minimizing operational downtime.

The AirVibe offers a variety of full-scale ranges, accommodating diverse motor speeds and application requirements. This adaptability ensures precise data capture across different operational conditions.

The AirVibe sensor’s design incorporates a range of data output customization options, including high pass, low pass, and bandpass filtering capabilities. This flexibility allows for bespoke monitoring configurations tailored to the unique characteristics of each motor. The sensor's open architecture facilitates seamless integration with a variety of gateways and user-defined software systems. Additionally, the provision of source code in Python via Jupyter Notebook enhances ease of programming and integration, making the AirVibe highly versatile across numerous industrial applications.

Manufactured in the USA, the AirVibe is designed for durability. Its customizability for specific machine applications, multiple mounting options, and a standard 1-year warranty (extendable to 5 years) underscore its robustness and reliability. The sensor's production capacity to meet demands exceeding 100,000 units annually attests to its proven track record in industrial environments.

The sensor's broad frequency range, spanning 1Hz to 8000 Hz, renders it exceptionally versatile for diverse industrial settings. Its suitability for hazardous locations, IP68 waterproof standard compliance for submersible conditions (up to 30 feet in freshwater), and specialized impact monitoring mode, make it ideal for a wide range of industrial uses, including in compressor cylinders and reciprocating pumps.

AirVibe’s utilization of an external Lithium industrial D cell battery contributes to an extended operational lifespan of up to 8 years, with a milliamp hour capacity 5 to 20 times greater than competing products. The innovative magnet mount facilitates straightforward installation, and the detachable battery module from the sensor enables optimal sensor placement in challenging locations. This separation ensures increased battery longevity by situating the LoRa transmitter module away from harsh process conditions.

Conclusion

The AirVibe Wireless LoRa Sensor emerges as a technologically advanced, flexible, and dependable choice for industrial motor monitoring. Its features, including high-resolution data capture, customization options, robust construction, and application versatility, render it an indispensable asset in industrial settings. Its integration simplicity and cost-efficiency further underscore its practicality for widespread industrial use. Consequently, the AirVibe sensor is strongly recommended for entities aiming to augment their motor monitoring and maintenance protocols.

We can customize vibration solutions to fit your needs

Request For QuoteRecommended Products

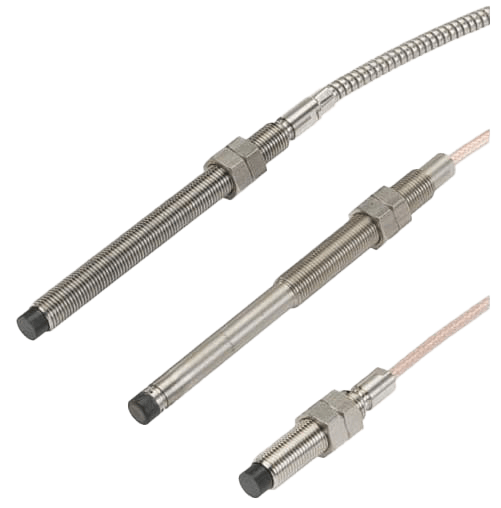

- TwinProx (sleeve or oil-lubricated bearings)

- Proximity Probes (sleeve or oil-lubricated bearings)

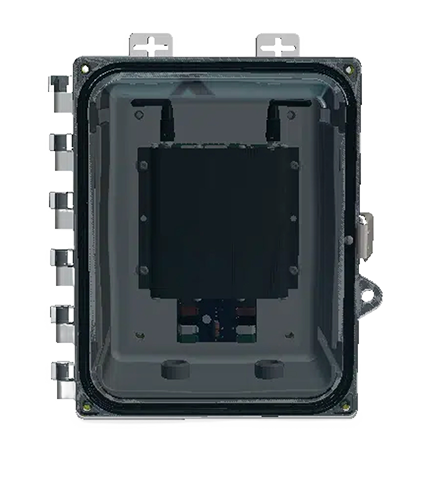

- Airvibe and Machine Gate (Wireless installation on Roller element bearings)

- Trivibe (Continuous near real-time data on roller element bearings)

Why choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us