Gearbox Vibration Monitoring & Analysis

Gearboxes and transmissions are critical components in various industrial applications, often subjected to intense operational stress. Vibration-related issues can significantly impair their efficiency and lifespan. Implementing Trivibe sensors from Machine Saver can effectively monitor and mitigate these challenges. The gearbox vibration analysis report outlines the technical advantages and financial benefits of using Trivibe sensors for gearboxes and transmissions, highlighting common vibration problems.

Common Vibration Failures in Gearboxes and Transmissions

- Gear Misalignment and Wear: Misalignment or wear of gears can lead to uneven distribution of forces and increased vibration.

- Bearing Failures: Bearings in gearboxes and transmissions are prone to wear and failure, leading to increased vibration and potential breakdowns.

- Imbalance: Imbalance in rotating components can cause excessive vibration, accelerating wear and reducing efficiency.

- Loose Components: Bolts, couplings, and other components can become loose due to continuous operation, causing abnormal vibrations.

- Lubrication Issues: Inadequate lubrication can lead to increased friction and vibration within the gearbox or transmission.

Technical Considerations

High-Resolution Vibration Detection:Trivibe's ability to capture over 50,000 samples per second enables precise detection of the slightest imbalances or irregularities.

- Benefit: Early detection of potential issues allows for timely maintenance, reducing the risk of catastrophic failure.

The sensor’s customizable filter options enable specific tuning to the operational characteristics of different gearboxes and transmissions.

- Benefit: Enhanced accuracy in monitoring, leading to more effective maintenance strategies.

The RS485 port facilitates easy integration with various industrial control systems.

- Benefit: Simplifies installation and enhances data accessibility and management.

Designed to withstand industrial conditions, Trivibe is well-suited for the demanding environments of gearboxes and transmissions.

- Benefit: Reliable long-term performance in harsh operational conditions.

Financial Considerations

Reduction in Maintenance and Downtime Costs:By enabling predictive maintenance, Trivibe can significantly decrease the frequency and severity of unscheduled downtimes and repairs.

- Benefit: Long-term cost savings through improved operational efficiency and reduced maintenance expenses.

The initial investment in Trivibe sensors is offset by the long-term financial benefits of reduced maintenance needs and extended equipment life.

- Benefit: Improved return on investment over time.

The design of the Trivibe sensor allows for straightforward installation, reducing initial setup costs.

- Benefit: Economical and less disruptive installation, especially important in complex industrial setups.

Conclusion

Incorporating Trivibe sensors into gearboxes and transmissions is a strategic decision that offers both technical and financial benefits. Technically, the sensors provide precise gearbox vibration monitoring, crucial for early problem detection and efficient maintenance of these critical components. Financially, the reduction in maintenance costs and downtime, combined with the long-term operational efficiency gains, make Trivibe sensors a valuable investment for industrial applications relying on gearboxes and transmissions for their operations.

We can customize vibration solutions to fit your needs

Request For QuoteRecommended Products

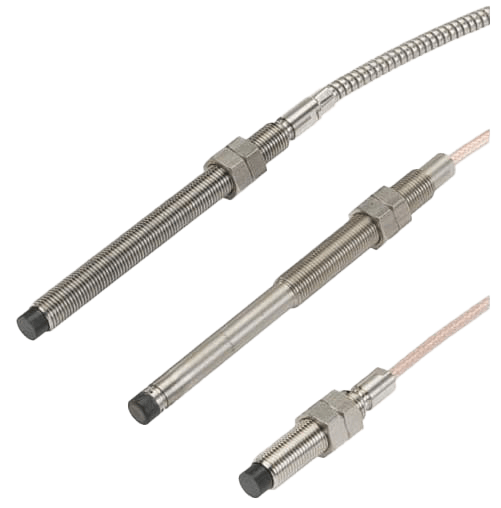

- TwinProx (sleeve or oil-lubricated bearings)

- Proximity Probes (sleeve or oil-lubricated bearings)

- Airvibe and Machine Gate (Wireless installation on Roller element bearings)

- Trivibe (Continuous near real-time data on roller element bearings)

Why choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us