Chillers Vibration Monitoring & Analysis

Industrial chillers are critical components in many industries, and their efficient operation is vital. Vibration-related issues in chillers can lead to inefficiencies and breakdowns. The Trivibe sensor from Machine Saver offers a solution to monitor and address these issues. The chillers vibration analysis report provides an analysis of the financial and technical benefits of using Trivibe sensors for industrial chillers, including common vibration failures.

Common Vibration Failures in Industrial Chillers

- Imbalance: Caused by uneven weight distribution in rotating parts. Leads to excessive vibration and potential mechanical wear.

- Misalignment: Occurs when the motor and compressor shafts are not properly aligned. Causes uneven forces and vibrations.

- Bearing Failures: Bearings can fail due to wear, inadequate lubrication, or overloading, leading to increased vibration.

- Loose Components: Over time, bolts and fasteners may loosen, causing abnormal vibrations.

- Resonance: When the operational frequency matches the system’s natural frequency, leading to amplified vibrations.

Technical Considerations

High-Resolution Vibration Analysis:Trivibe’s capability to capture over 50,000 samples per second is crucial for early detection of imbalances, misalignments, and bearing issues.

- Benefit: Enables timely maintenance actions before major failures occur.

With high pass, low pass, and band pass filters, Trivibe can be tailored to specific vibration profiles of chillers.

- Benefit: Provides more accurate and relevant monitoring, enhancing predictive maintenance strategies.

RS485 port allows easy integration with existing control systems.

- Benefit: Simplifies monitoring processes and enhances data accessibility.

Trivibe’s design is suited for the industrial environment, ensuring consistent performance.

- Benefit: Reliable data over time, even in harsh operational conditions.

Financial Considerations

Reduction in Maintenance and Downtime Costs:Early detection of vibration issues reduces the need for emergency repairs and unscheduled downtimes.

- Benefit: Saves on costly repairs and prevents loss of productivity.

Although the initial investment in Trivibe sensors might be higher, the long-term savings from reduced maintenance and operational efficiency are significant.

- Benefit: Improved ROI due to enhanced chiller longevity and reduced repair frequency.

Daisy-chaining capability reduces installation complexity and costs.

- Benefit: More cost-effective installation compared to traditional vibration monitoring systems.

Conclusion

Implementing Trivibe vibration sensors for HVAC cooling units is a wise decision both technically and financially. Technically, the sensors offer high-resolution data and customizable output, crucial for early detection of common vibration failures such as imbalance, misalignment, and bearing failures. Financially, the sensors lead to significant savings by reducing maintenance costs, downtime, and improving the overall efficiency and lifespan of chillers. The Trivibe sensor system, therefore, presents a strategic investment for maintaining the health and efficiency of industrial chillers.

We can customize vibration solutions to fit your needs

Request For QuoteRecommended Products

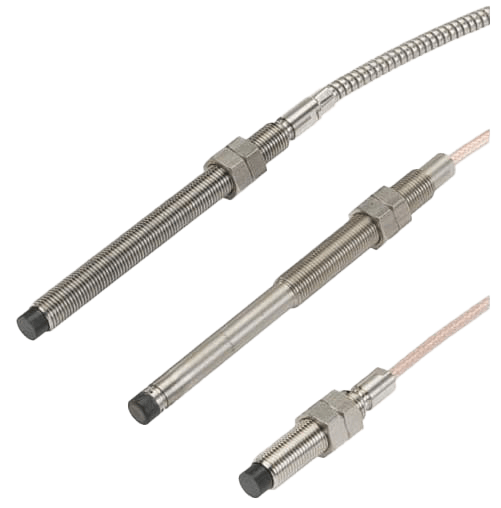

- TwinProx (sleeve or oil-lubricated bearings)

- Proximity Probes (sleeve or oil-lubricated bearings)

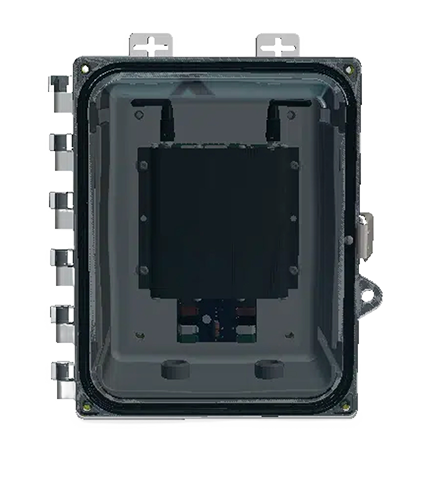

- Airvibe and Machine Gate (Wireless installation on Roller element bearings)

- Trivibe (Continuous near real-time data on roller element bearings)

Why choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us