Vibration Sensors for Industrial Engines

Engine vibration monitoring for optimal performance and longevity is a critical task, and the Trivibe Sensor offers a technologically advanced solution. This report focuses on the benefits and capabilities of the Trivibe sensor in the context of industrial engine monitoring.

High-Resolution Data for Engine Analysis

The Trivibe sensor's ability to capture over 50,000 samples per second provides high-resolution vibration data, essential for detecting early signs of engine issues like misfires, imbalances, and bearing wear. Advanced ML/AI vibration analysis techniques enable predictive maintenance, reducing downtime and prolonging engine life.

With dynamic data output that can be customized with high pass, low pass, and band pass filters, the sensor is tailored to specific engine vibration profiles. Its RS485 port ensures digital integration with various control systems, and the Python source code on Jupyter Notebooks simplifies integration and programming for diverse engine monitoring needs.

Manufactured in the USA, the Trivibe sensor withstands demanding industrial engine environments. Customizable designs for specific engine applications, various mounting options, a standard 1-year warranty extendable to five years, and the ability to meet high demand attest to its reliability and quality.

Suitable for a range of industrial engines, the sensor’s broad frequency range (0.8 Hz to 6000 Hz) and internal RTD temperature measurement enhance its applicability. The IP68 waterproof standard and submersible capabilities ensure reliable performance under challenging conditions.

Daisy-chaining capability reduces installation costs and complexity, particularly beneficial in settings with multiple engines. The sensor's long lifespan and minimal maintenance needs contribute to its cost-effectiveness.

A key feature of the Trivibe sensor is its ability to monitor engine detonation and timing errors, which are critical for engine health. Incorrect timing can lead to backfiring, a hazardous condition that can damage the engine. The sensor’s high-resolution data allows for the detection of abnormal vibration patterns indicative of detonation or timing discrepancies. This early detection capability enables timely adjustments to the engine's timing system, preventing backfiring and ensuring the engine runs smoothly and efficiently. This feature is particularly important in industrial settings where engine reliability and safety are paramount.

Conclusion

The Trivibe Wireless Sensor is an exceptional choice for industrial engine vibration monitoring, offering high-resolution data capture, customizable features, robust construction, and versatility. Its capability to monitor detonation and timing errors adds a crucial layer of safety and efficiency, making it a valuable tool for industries reliant on the consistent and safe operation of their engines.

We can customize vibration solutions to fit your needs

Request For QuoteRecommended Products

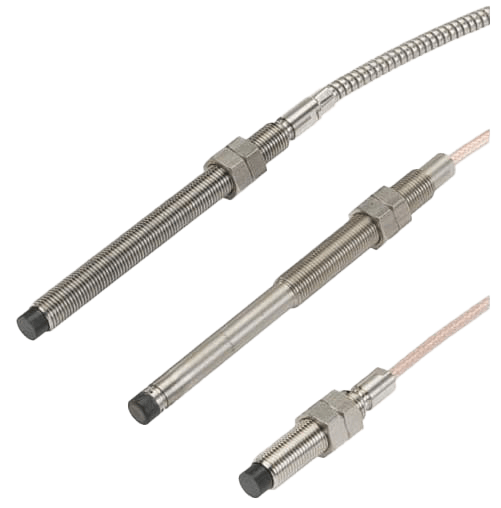

- TwinProx (sleeve or oil-lubricated bearings)

- Proximity Probes (sleeve or oil-lubricated bearings)

- Airvibe and Machine Gate (Wireless installation on Roller element bearings)

- Trivibe (Continuous near real-time data on roller element bearings)

Why choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us