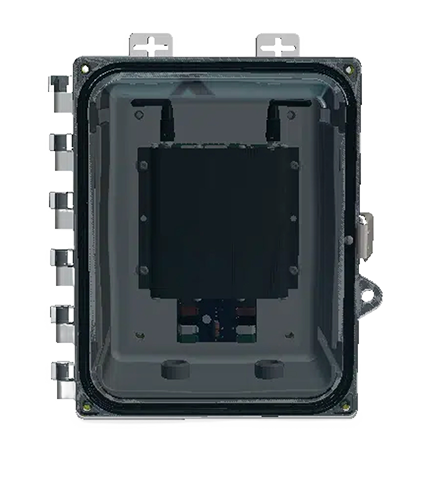

Wireless Vibration Sensor

Are you ready for a game-changing advancement in vibration monitoring? Machine Saver, Inc. proudly presents the Airvibe Vibration Sensor – the future of predictive maintenance.

- Cutting-Edge LoRaWAN Connectivity: Airvibe Vibration sensor leverages the latest in LoRaWAN wireless communication technology, delivering high-resolution time waveform data with unmatched precision.

- Extended Battery Life: Unlike most battery-powered sensors, Airvibe vibration sensor boasts an impressive 4-8 years of battery life. Say goodbye to frequent battery changes and hello to uninterrupted monitoring.

- Heat-Resistant Design: Our unique design moves the battery and communication module away from the heat on the bearing, ensuring reliable performance even in high-temperature environments, withstanding up to 105°C.

- Long-Distance Data Transmission: Airvibe can transmit time waveform and overall data for 8 miles or more in some cases, offering exceptional range and flexibility.

- Long Range & Deep Penetration: Sensors can be located indoors, outdoors, or underground and still communicate directly to the gateway within a range of up to 50 km in open areas and up to 10 km in urban environments. No need for overly complex coverage analysis.

- Low Power: Low bit rates and asynchronous communications ensure low energy consumption. Sensors are designed to send small data bits when required, whether event-driven or scheduled, and battery life can last up to 10 years.

- High Network Capacity: The adaptive data rate and multichannel multi-modem transceiver in the gateway enable simultaneous messages on multiple channels. This provides a LoRaWAN® network with very high capacity and scalability.

- Open Standard Unlicensed Band: The LoRaWAN® specification is supported and maintained by the LoRa Alliance® allowing seamless and quick scalability. LoRa® technology typically operates in the unlicensed spectrum, and is ideal for public and private networks.

- Built-in Security: Network server security guarantees the authenticity of devices in the network, and secure applications ensure end-user data is protected and confidential. LoRa® has AES-128 encryption built-in as standard.

- Ease of Installation: LoRaWAN® protocol uses a star topology. Gateways can provide coverage for a very large area, and low cost, long-lasting battery-operated sensors can be installed with no need for power source wiring or constant maintenance operations.

- Low Cost: LoRa® gateways are stateless and do not have to establish a session to communicate with a sensor. As a result, gateways and sensors provisioning is efficient and reduces costs of deployment. In addition, LoRaWAN unlicensed frequency bands are free to use.

- Growing Ecosystem: An expanding and mature ecosystem across every part of the IoT value chain. Collaboration through the LoRa Alliance ensures Interoperability, compliance, and growth of the LoRaWAN® protocol.

NanoWipom software available to view Airvibe data remotely.

One of the few available wireless sensors on the market that provides powerful frequency data insights to determine the root cause of vibration alarms remotely.

Why Airvibe Stands Out:

Airvibe is not just another wireless vibration sensor; it's a leap forward in the industry. Here's why it's different:

- Precision Data: Our LoRaWAN technology enables us to provide high-resolution time waveform data, offering insights that other sensors can't match.

- Extended Battery Life: Airvibe's innovative battery placement means you can enjoy 4-8 years of uninterrupted monitoring, setting it apart from typical battery-powered sensors.

- Heat Resilience: Built to withstand high temperatures, Airvibe ensures reliable performance even in the toughest industrial environments.

- Seamless Connectivity: Airvibe's LoRaWAN connectivity offers exceptional range, deep penetration, and low power consumption, making it perfect for a wide range of applications.

Experience the Future of Vibration Monitoring

Discover the unmatched precision, durability, and reliability of Airvibe. Don't compromise on your machinery's health – choose the sensor that sets the new standard.

Similar Products

Check out similar product for your vibration monitoring applications.

NanoWipom Online Data Suite

You don’t have to wait for your machine to fail so Artificial Intelligence can learn. Our Artificial Intelligence algorithms have been learning with a data base generated for 15 years from more than 60,000 machines analyzed per month.

Learn More

MachineGate

This compact and powerful device offers real-time insights into the vibrations affecting your equipment, allowing you to detect issues early, prevent costly downtime, and extend the lifespan of your assets.

Learn More

Machine Cloud ML+AI

A revolutionary solution that combines the power of machine learning and the expertise of human reliability analysts to provide you with unparalleled predictive maintenance capabilities.

Learn More

TriVibe Vibration Sensor

From the highly detailed data that it outputs, this sensor is capable of detecting bearing and machine process failures months before it becomes catastrophic damage to your machine.

Learn MoreWhy choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us