Proximity Vibration Monitoring Equipment

Fast Delivery and Market Leading Quality: Vibration Probes for Your Oil-Lubricated and Sleeve Bearings. Get most common probes in 2-days delivery time.

We manufacture all market equivalents in the USA.

What are Proximity Probes?

Non-contact vibration proximity probes are essential tools for monitoring the vibration of rotating machinery like turbines, pumps, compressors, and motors, aiding in predictive maintenance and ensuring optimal performance and safety. They work by detecting variations in the magnetic field generated by the rotating shaft, providing data on vibration amplitude and frequency. This data enables analysis of machinery condition, detection of faults, and scheduling of maintenance, all crucial for preventing failures, reducing downtime, and prolonging machinery lifespan.

We build the following BN probe equivalents, as well as other leading manufacturer equivalents for the following probe systems:

- 3300 Series

- 3309 (Focus View) Series

- 3000 Series

- 7200 Series

Large oil-lubricated bearings and sleeve-bearing machines are the backbone of countless industrial operations. Yet, their potential for catastrophic failure can cause significant downtime, safety hazards, and substantial financial losses. Most are not properly monitored because they cannot cost-justify continuous time waveform data using a vibration proximity system.

Our vibration probes offer a proactive solution for preventing these risks. By monitoring vibration levels and analyzing trends, you can:

- Detect early signs of bearing wear and fatigue

- Schedule proactive maintenance before failure occurs

- Extend the lifespan of your bearings

- Optimize lubrication and operating conditions

- Reduce downtime and maintenance costs

- Promote workplace safety

Our Diverse Probe Portfolio

3300 Series Equivalent- Unparalleled Sensitivity: The 3300 series probes boast exceptional sensitivity, allowing you to detect even the slightest changes in vibration levels, even in the most demanding environments.

- Rugged and Reliable: Built to withstand harsh industrial settings, the 3300 series probes ensure accurate and dependable data collection over the long haul.

- Versatile Connectivity: Integrate seamlessly with your existing monitoring systems and software for comprehensive data analysis and visualization.

- Cost-Effective Solution: The 3000 series provides exceptional value, offering high-quality performance at an affordable price point.

- Simple Deployment: Designed for easy installation and configuration, the 3000 series probes fit seamlessly into your existing maintenance routine.

- Reliable Performance: Enjoy consistent and accurate data collection with the 3000 series' robust design and advanced sensor technology.

- No Cross Talk: These specialized probes provide clear visibility into tighter bearings, allowing you to monitor bearings in difficult-to-reach locations without cross-talk from other probes.

- Uncompromising Performance: Focus view probes offer superior sensitivity and reliability, ensuring you don't miss any critical data points.

- Maximize Efficiency: Optimize your maintenance routine by eliminating the need for disassembly or relocation of equipment.

- Tailored Solutions: Our team of experts can design and develop custom vibration probes to meet your specific needs and bearing configurations.

- Advanced Functionality: Integrate additional sensors and features like temperature monitoring, oil analysis, and acoustic emission detection.

- Unlock Unprecedented Insights: Gain deeper understanding of your bearings' health and performance with a customized monitoring solution.

- Expert Guidance: Our dedicated team of engineers and technicians provides comprehensive support throughout the entire process, from selection and configuration to installation and data analysis.

- Training and Resources: Access a wealth of online resources and training materials to ensure you get the most out of your vibration probes.

- Unmatched Reliability: We offer a comprehensive warranty and service program to ensure your equipment operates at peak performance.

Invest in Proactive Maintenance

Don't wait for a catastrophic failure to cripple your operations. Implement a proactive maintenance program with our advanced vibration probes and experience the benefits of:

- Reduced downtime and maintenance costs

- Increased operational efficiency and productivity

- Enhanced safety and reliability

- Extended lifespan of your valuable assets

Contact us today to discuss your specific requirements and explore the perfect vibration probe solution for your large oil-lubricated bearings.

Leading Proximity Solutions

Machine Saver probes are at the forefront of eddy current proximity probe design, are well acknowledged in the industry, and are compatible with all significant transducer producers.

The American Petroleum Institute Standard 670 is completely complied with by the MS-Series probes (API-670). We guarantee the viability and durability of these proximity probes and associated systems for up to ten years, with a default warranty of three years that is extendable to five years at the customer's request. We are the only known American manufacturer of mass-produced vibration probes.

To support a preventative maintenance program and machinery diagnostics, today's high-performance eddy current proximity sensors provide continuous condition monitoring information and trip-monitored machines when necessary.

Our leading proximity solutions provide full interoperability and exceptional performance in challenging environments.

Non-Contact Proximity Probe System

An industrial non-contact proximity probe typically consists of a coil, a mandrel, and a cable. Here's how these components are combined to make the probe:

- Coil: The coil is typically made of a fine wire wound around a former, which is usually made of a non-conductive material. The coil is a critical component of the probe, as it generates the electromagnetic field that interacts with the target object.

- Mandrel: The mandrel is a tubular structure that is typically made of a non-magnetic material, such as stainless steel or titanium. The coil is wound around the mandrel, which helps to keep it in place and maintain its shape.

- Cable: The cable is used to connect the probe to the driver and signal conditioning electronics, which are typically located outside the sensing environment. The cable is typically made of a shielded coaxial cable that is designed to minimize noise and interference.

To assemble the probe, the coil is wound around the mandrel, which is then typically coated with a layer of insulating material to protect the coil from the environment. The cable is then attached to the coil, and the entire assembly is typically mounted on a support structure, such as a bracket or flange.

When the probe is in operation, the electromagnetic field generated by the coil interacts with the target object, which induces eddy currents in the object. These eddy currents generate a secondary electromagnetic field that is detected by the coil, and the resulting signal is then transmitted through the cable to the driver and signal conditioning electronics for processing and analysis.

An industrial non-contact proximity probe typically consists of the following components:

- Sensor Head: This is the part of the probe that detects changes in position and proximity of the target. It typically uses electromagnetic or capacitive sensing technology.

- Signal Processing Unit: This unit is responsible for processing the sensor signals and converting them into electrical signals that can be read by a monitoring system or control unit.

- Amplifier: The amplifier boosts the signal from the sensor head to improve its accuracy and reliability.

- Cable: This connects the sensor head to the signal processing unit and can be shielded to reduce electromagnetic interference.

- Mounting Hardware: This allows the probe to be securely attached to the machine or equipment being monitored.

- Power Supply: The probe requires a power source, which can be supplied by batteries or an external power supply.

- Output Display: This component displays the output of the probe, which can include the distance or position of the target.

Resources

Gallery

Similar Products

Check out similar product for your vibration monitoring applications.

AirVibe Wireless

Using the low-power, open LoRawann Protocol to get actionable machinery health data to reduce downtime and preventable, catastrophic machinery failures.

Learn More

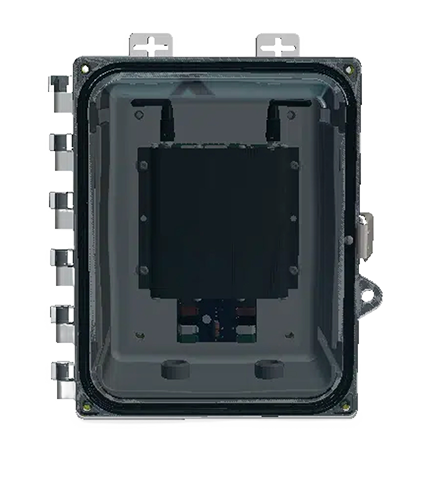

MachineGate

This compact and powerful device offers real-time insights into the vibrations affecting your equipment, allowing you to detect issues early, prevent costly downtime, and extend the lifespan of your assets.

Learn More

TwinProx Digital Prox Transmitter

From the highly detailed data that TwinProx outputs, this transmitter is capable of detecting problems on machines with journal bearings.

Learn More

TriVibe Vibration Sensor

From the highly detailed data that it outputs, this sensor is capable of detecting bearing and machine process failures months before it becomes catastrophic damage to your machine.

Learn MoreWhy choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us