Industrial Vibration Sensor

Are you ready for a game-changing advancement in vibration monitoring? Machine Saver, Inc. proudly presents the Trivibe 2.0 industrial Vibration Sensor – the legacy Trivibe you know and love, with all the same existing setups with even more features and customization added.

- 3-Axis Digital Vibration and Temperature Sensor: It is an industry-leading industrial vibration sensor capable of 50,000+ vibration samples per second. This feature makes it highly suitable for gathering data for analytical vibration software and Machine Learning AI applications.

- Digital Triaxial Accelerometer and Temperature Sensor: The TriVibe sensor is specifically designed to monitor machines' ball bearings, roller bearings, and gear conditions, ensuring comprehensive machinery health monitoring.

- Versatility and Integration: It can interface using Modbus RTU RS485 with the plant DCS, PLC, SCADA, or function as a standalone machine protection monitor. This flexibility allows for easy integration into various industrial systems.

- Efficiency and Cost-Effectiveness: The TriVibe is designed as an all-in-one solution to continuously protect and monitor the condition of machinery, making it ideal for both balance of plant and critical equipment.

- Comprehensive Monitoring Capabilities: The vibration analysis sensor can measure and monitor overall vibration in units of acceleration, velocity, and displacement in the X, Y, and Z axis. It also includes bearing temperature and impact monitoring.

- Output and Control Features: The TriVibe provides Modbus RS-485 outputs. It also features adjustable startup, trip delay times, and programmable filters for tailored usage according to specific requirements.

- Impact Mode Configurable: The TriVibe can be pre-order configured to be set to impact mode. This feature allows for the vibration sensor to output counts of vibration "impacts" as well as amplitude severity of each impact to both monitor for mechanical looseness as well as high impact end stages that can be damaging to reciprocating machinery. This is highly useful for some reciprocating pumps and recip compressor cylinders.

Why Trivibe 2.0 Stands Out

Trivibe 2.0 is not just another vibration sensor; it's a leap forward in the industry. Here are the typical sensor pain points it solves:

- Limited Axis Measurement and low sampling: Some sensors have lower sampling rates and are not 3 axis, which may miss critical data points. The TriVibe's high sampling rate of over 50,000 samples per second ensures detailed and accurate data capture, crucial for early detection of potential issues.

- The wrong sensor for the wrong machine speed or application: 2.0 is a on size fits all sensor for all roller element baring machines

- Complex Integration with Control Systems: Integrating different sensors into existing control systems (like DCS, PLC, SCADA) can be challenging. The TriVibe offers versatile connectivity options with Modbus RTU RS485

- Cost and Complexity: Implementing multiple sensors for comprehensive monitoring can be costly and complex. The all-in-one design of the TriVibe makes it a cost-effective and simpler solution, reducing installation and maintenance efforts.

- Limited Customization and Flexibility: Some 4-20 mA, other digital sensors, and wireless sensors lack the flexibility to be adjusted for specific applications. The TriVibe provides adjustable startup, trip delay times, and programmable filters, allowing for customization to suit various operational needs.

- Inadequate Data for Machine Learning Applications: The Trivibe 2.0 is mass produced and sold in partnerships with a multitude of ML/AI applications beyond our own software offerings. This is mainly due to a combination of considering the cost, features, reliability, and customized trusted data the Trivibe 2.0 delivers.

Experience the Future of Vibration Monitoring

Discover the unmatched precision, durability, and reliability of Trivibe 2.0. Don't compromise on your machinery's health – choose the sensor that sets the new standard.

Similar Products

Check out similar product for your vibration monitoring applications.

AirVibe Wireless

Using the low-power, open LoRawann Protocol to get actionable machinery health data to reduce downtime and preventable, catastrophic machinery failures.

Learn More

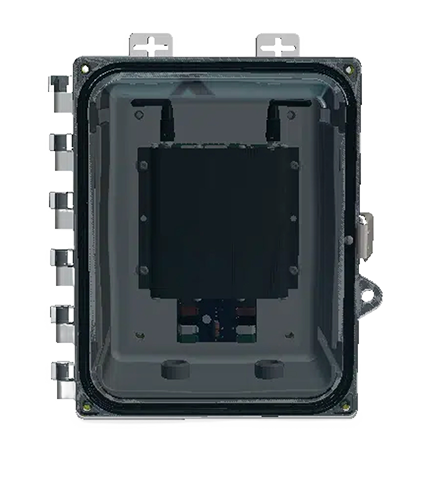

MachineGate

This compact and powerful device offers real-time insights into the vibrations affecting your equipment, allowing you to detect issues early, prevent costly downtime, and extend the lifespan of your assets.

Learn More

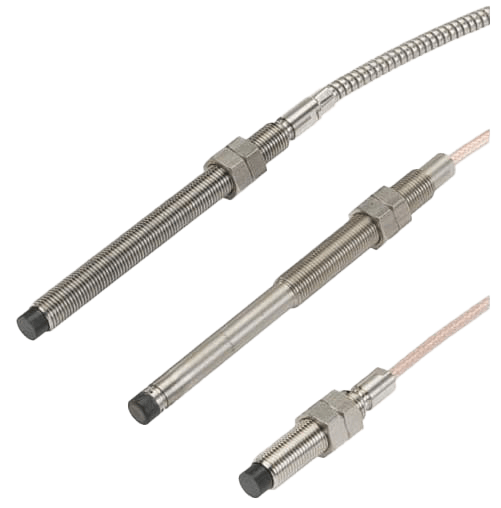

Proximity Probes

Machine Saver probes are at the forefront of eddy current proximity probe design, are well acknowledged in the industry, and are compatible with all significant transducer producers.

Learn More

TwinProx Digital Prox Transmitter

From the highly detailed data that TwinProx outputs, this transmitter is capable of detecting problems on machines with journal bearings.

Learn MoreWhy choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us