Proximity Probe Driver

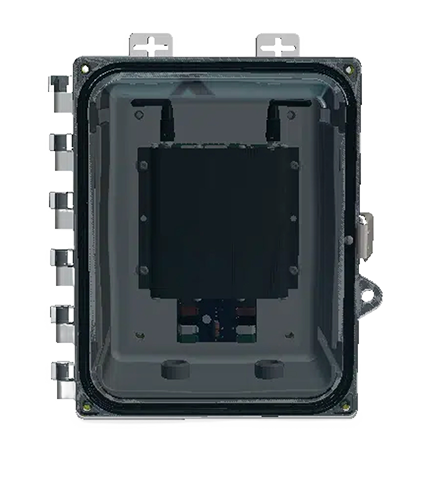

TWIN PROX MODBUS

Unlock unprecedented efficiency and cost savings with TwinProx, the dual-channel digital proximity transmitter that drives down costs by an average of 20.61% for OEMs and unprecedented amounts with our end users. With TwinProx, get access to continuous overall and time waveform data without the need for a rack mounted monitor and digital acquisition system.

What are Proximity Drivers?

Proximity Prove Drivers are the end point of the probe’s extension cable. It is where the voltage of the probe is produced to continue to a rack mounted monitor which then visualizes and sets rules for the driver’s output.

The simple way to remember the difference between probe drivers and transmitters, is that probe drivers are used with rack mounted monitors which can produce continuous frequency data, and transmitters are used to pass overall data back to controls, and sometimes make the frequency time waveform data available for a local manual collection via BNC connector.

Here's why TwinProx stands out in the world of proximity probe systems:

key features:- Advanced-Data Capture: Automatic capture and generation of time waveform, spectral vibration data, and orbit without the need for a rack. Provided to your controls or DCS via digital I/O with Serial Modbus RS485 RTU.

- Dual-Channel Excellence: TwinProx offers a unique 2-for-1 advantage, functioning as a dual-channel proximity probe driver out of the box.

- System set up Graphical User Interface which allows users in the field the ability to quickly set up.

- Out-of-the-box compatibility with other API670 style proximity probe systems, including renowned brands like 3300XL® and NSV®.

- MODBUS RTU RS485 interface for seamless integration with plant PLC, DCS, PC, and other data acquisition systems.

- Digital Calibration and linearization for perfect vibration readings in minutes.

- Accommodate various shaft target materials and perform digital linearization in the field within minutes.

- Includes product LEDs which can be programmed in the GUI to tell the installer when probes on each channel are perfectly gapped.

- Superior Elimination of Runout: Digital elimination of electrical and mechanical runout without the requirement for degaussing and burnishing the shaft. (Feature coming soon)

- Scalability and Compatibility: Connect up to 20 TwinProx units in series with color-coded wire terminals, daisy-chained per RS485 bus line.

- Reverse mount probe housing and DIN rail mounting options for enhanced flexibility.

- USA designed and manufactured for unparalleled quality.

- Design specificity tailored to customers' machine applications with API 670 design.

- 10 years of quality life expectancy, ensuring longevity and reliability.

- See our testing data for more accuracy at higher ranges across temperatures that beat out existing and previously industry-leading proximity systems.

- Peer-to-Peer Communication: TwinProx units communicate peer-to-peer, providing phase-synchronized vibration data across a sensor cluster and a sync probe.

- Informed Decision Making: Alarm logic is built into paired channels for more informed decision-making.

- Raw data dynamic output directly from TwinProx.

- Designed for various specifications and applications where proximity is crucial.

- Rod drop and rod position detection in reciprocating compressors.

- Reverse rotation detection in pumps and compressor cylinders.

In summary, TwinProx redefines the landscape of proximity probe systems, offering unparalleled accuracy, efficiency, and cost savings. Elevate your machinery's performance with the cutting-edge technology and user-friendly features of TwinProx. Order now and experience a new era of proximity sensing excellence.

TwinProx Voltage Out (VO)

The plug n play replacement for existing probe drivers within rack mounted monitoring system and OEM replacements:

Setting up proximity systems is hard, so we thought we should make it easy-- With TwinProx VO Graphical User Interface (GUI), get easy access to plug into the Twin Prox VO driver and make one single 2-channel device pre-setup for ALL proximity systems from all probe manufacturers, set gapping distances to make the LED lights react when probe is properly gapped, and then linearized the probe all in the field in minutes.

Here's why TwinProx VO stands out in the world of proximity probe systems:

Key Features:- One Probe Driver for all proximity systems. Smart and can be edited to accept ANY probe type. Our OEM customers enjoy having one single driver for all specified probe system lengths, manufacturers, and series.

- Dual-Channel Excellence: TwinProx offers a unique 2-for-1 advantage, functioning as a dual-channel proximity probe driver out of the box.

- System set up Graphical User Interface which allows users in the field the ability to quickly set up.

- Out-of-the-box compatibility with other API670 style proximity probe systems, including renowned brands like 3300XL® and NSV®.

- Voltage Output that seamlessly connects to existing rack-mounted monitors.

- Digital Calibration and linearization for perfect vibration readings in minutes.

- Accommodate various shaft target materials and perform digital linearization in the field within minutes.

- Includes product LEDs which can be programmed in the GUI to tell the installer when probes on each channel are perfectly gapped.

- See our testing data for more accuracy at higher ranges across temperatures that beat out existing and previously industry-leading proximity systems.

- USA designed and manufactured for unparalleled quality.

- Design specificity tailored to customers' machine applications with API 670 design.

- 10 years of quality life expectancy, ensuring longevity and reliability.

- Designed for various specifications and applications where proximity is crucial.

- Rod drop and rod position detection in reciprocating compressors.

- Reverse rotation detection in pumps and compressor cylinders.

TwinProx VO redefines the landscape of proximity probe systems, offering unparalleled accuracy, efficiency, and cost savings. Elevate your machinery's performance with the cutting-edge technology and user-friendly features of TwinProx. Order now and experience a new era of proximity sensing excellence.

Similar Products

Check out similar product for your vibration monitoring applications.

AirVibe Wireless

Using the low-power, open LoRawann Protocol to get actionable machinery health data to reduce downtime and preventable, catastrophic machinery failures.

Learn More

MachineGate

This compact and powerful device offers real-time insights into the vibrations affecting your equipment, allowing you to detect issues early, prevent costly downtime, and extend the lifespan of your assets.

Learn More

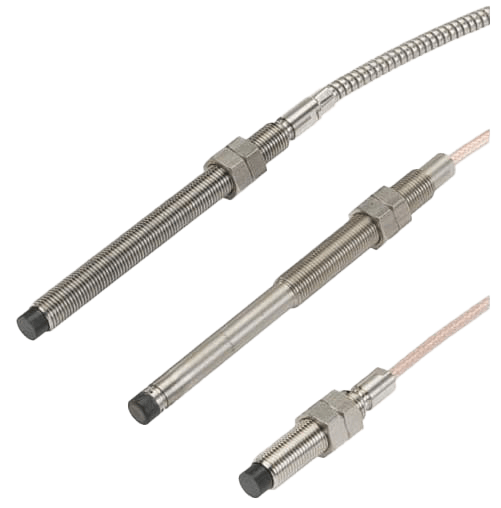

Proximity Probes

Machine Saver probes are at the forefront of eddy current proximity probe design, are well acknowledged in the industry, and are compatible with all significant transducer producers.

Learn More

TriVibe Vibration Sensor

From the highly detailed data that it outputs, this sensor is capable of detecting bearing and machine process failures months before it becomes catastrophic damage to your machine.

Learn MoreWhy choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us